| Engineered Lifting Systems recently completed the control modernization of a Refuse Crane (Refuse to Power Generation) from old Kone Thyristor Control to Magnetek VG+ and G+ drives. |

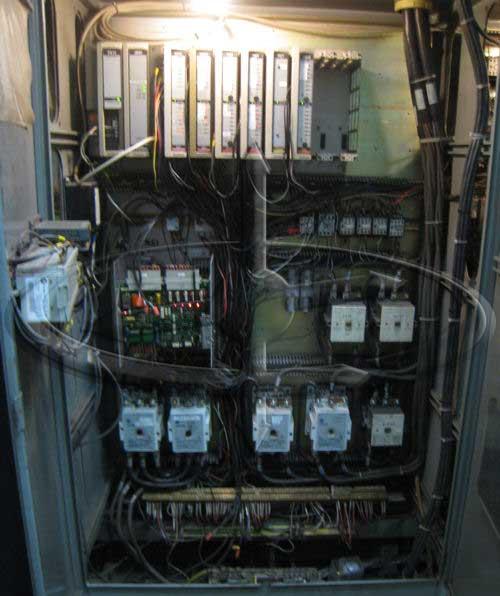

| OLD CONTROLS Click on images for a larger view. |

|

| MODERNIZED CONTROLS |

|

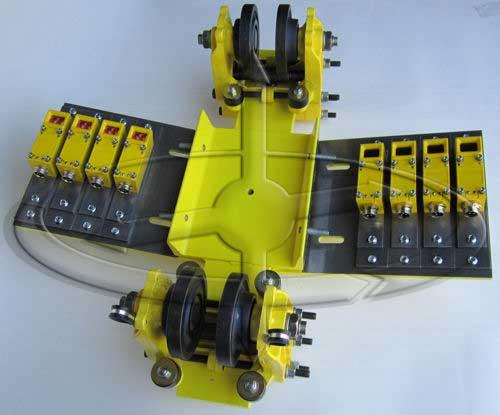

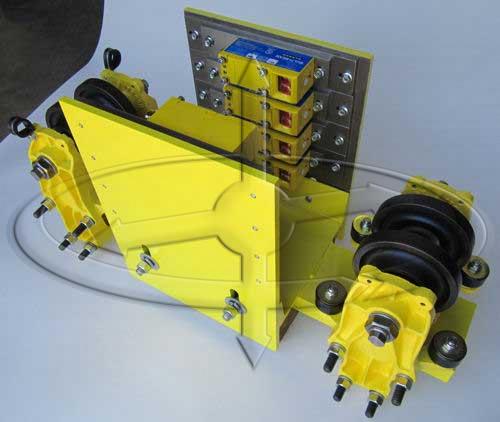

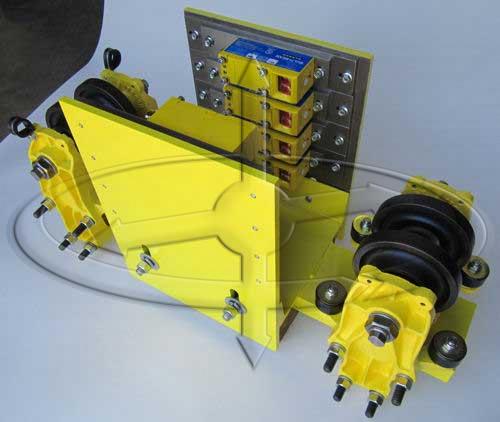

| As this crane runs 24/7, it has segmented automation that allows the operator push button control of repeated functions for the crane. A major part of that automation is a reader trolley that, using a series of holes in a monorail beam and light emitting sensors, provides the PLC with location references for the crane. |

|

| The original reader trolley used incorrect trolley assemblies, a frame that was warped, and one of the trolley frames was bent. This led to low repeatability in the programs, and ultimately no ability to use the automatic features.We took the old design and engineered a new trolley using the correct sub-assemblies, and a frame that while accurate to .002”, also allowed for maximum sensor head adjustment. |

| Download a copy of the Final Trolley |

| This new design also allowed drop down sides that provided maximum access to the sensor heads without having to remove the Reader Trolley from the monorail. |

|

| Since installation this new Reader Trolley has been working without a flaw. The operators and maintenance people are all happy with the renewed operation and reliability. |

|

| Contact the Crane Doctor today and find out how Engineered Lifting Systems can help your cranes and improve performance. ebrown@engineeredlifting.com |

Recent news posts

This is a sample blog post title.![Featured Image]()

Gravity Latch with Rotation Lock

This is a sample blog post title.![Featured Image]()

Magnetek Series 3 Drives Using “Motor 2” Option

This is a sample blog post title.![Featured Image]()

Magnetek Brake Circuit Fusing

This is a sample blog post title.![Featured Image]()

Crane Cab Replacement Improves Function

This is a sample blog post title.![Featured Image]()