One of the most important crane modernization, retrofit or repair considerations is the replacement of outdated or unserviceable crane brakes with current industrial braking technology. Engineered Lifting Systems offers expert analysis and recommendations for your crane modernization and Mondel Industrial Brakes are our preferred choice for improving crane performance, safety and reducing maintenance and crane down time. Read more about these excellent products and contact Engineered Lifting for assistance.

Thruster Brakes by Mondel

Mondel Hy-Thrust Actuators combine all the basic elements of a hydraulic system into one integral unit, the function of these actuators is to convert electrical energy, hydraulically, into a mechanical force, producing a straight line thrust throughout the piston stroke.

These thruster brake actuators are electro-hydraulic devices which combine all the basic elements of a hydraulic system into one integral unit, consisting of: an electric motor driving a hydraulic pump, piping, working cylinder and piston.

There are three families of Mondel Thruster Brakes:

- AC Industrial Type “Ed”

- AC Explosionproof Type “EdF”

- DC Industrial Type “Eg”

Standard Features:

- Fast response – 2000 cycles per hour

- Long service life with minimum maintenance

- Bi-directional operation

- Extending forces from 50 lbs. to 770 lbs.

- Strokes from 2″ to 7.8″

- Operating ambient temperature: -25 Deg. C to +50 Deg. with standard fluid (other ranges available on request) V DC (Ed50/6 upwards)

Options:

- Internal compression spring

- Externally adjustable, stepless time delays – both directions (S) (H)

- Damping spring (D)

- Vacuum poured stator windings

- Tropical and corrosion protection

- Internal pipe heaters for below -30 Deg. C ambient (110V or 220V)

- Flameproof models available (EdF30/6 upwards)

- Continuously rated (S1) Intermittent rated (S3) Service < 40 Deg. C

- Class F insulation

- AC Supplies (Type Ed): 230V-460V-575V/3Ph/50-60Hz

- DC Supplies (Type Eg): 230V DC and 440

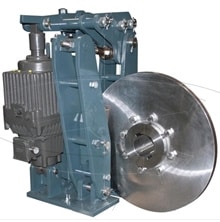

Mondel Industrial Disc Brakes

Mondel Type 400D severe duty range industrial disc brakes are specifically designed for high-speed, high-performance applications. They are manufactured from materials selected to optimize performance and serviceability for the most demanding applications.

Mondel’s advanced design features, combined with heavy duty steel construction and superior components, make this range of brakes your best choice for applications requiring optimal performance, reliability and durability. Plus, Mondel Disc Brakes are designed to be easy to service and maintain. Need a customized braking system for your application? Mondel Disc Brakes can be customized to meet your specific needs. Use our 400D as a drop-in replacement for your existing disc brakes or, with modifications, as a replacement for your existing drum brakes in high duty cycle, high speed or high torque stopping applications.

Specifications:

The Mondel 400D range of disc brakes are available in three types:

- Type SDT – conform to container industry ratings and dimensions

- Type ADT – conform to AISE ratings and dimensions

- Type NDT – conform to Wagner dimensions

Standard Features:

- External Torque Spring: Allows user to fine tune braking torque per application

- Auto-Adjust: Compensates for lining wear automatically

- Auto-Equalization: Insures equal shoe clearance at all times

- Steel-back Anti-friction Bronze Bushings: Installed at all main pivot points; reduces maintenance and enhances brake performance

- Stainless steel pivot pins: Non-corrosive-low maintenance

- Hy-Thrust Actuator: High performance, high duty cycle, waterproof thruster

- Easily replaceable brake shoes: Accessible brake shoe mounting hardware reduces maintenance time

- Non-asbestos brake linings

- CSA Approved

Optional Features:

- Time Delay on “Set” and “Release”

- Manual latching hand release

- Limit Switches for release proving

- Braketronic™ Controller

- Nitride Corrosion Protection

- Dual disk brake mounting plate

Applications Include:

- Marine Port Terminals

- Steel Mills

- Ship Loaders

- Port Cranes

- Shipyard Cranes

- Offshore Drilling Rigs

- Large Gantry Cranes

- Swing Span Bridges

- Bascule Bridges

- Vertical Lift Bridges

Accessories:

- Discs-Standard/Ventilated

- Discs/Hubs (Rigid)

- Discs/Couplings (Flexible)

AISE-NEMA Mill Duty Shoe Brakes (300M)

Mondel AISE-NEMA rated mill duty brakes are designed for heavy duty steel mill and other arduous environments, which require high integrity products with a minimum of maintenance and downtime.

Mondel’s mill duty shoe brakes advanced design features, combined with fabricated steel construction, makes this range of brakes suitable for applications requiring reliable braking with the minimum of maintenance and downtime, including: Steel Mills, Stacker Reclaimers, Shiploaders, Port Cranes, Shipyard Cranes, Offshore Drilling Rigs, Missile Assembly Cranes, Incinerator Cranes, Large Gorillas etc.

Specifications:

TYPE “MBE” – DC MAGNET

Note that these brakes are a direct replacement for P & H SBE Brakes

Spring applied, electrically released

- Replaceable magnet coils

- Class F insulation

- Shunt: 12V through 550V DC

- Series: 10A through 800A (40% – 10% FLC)

Options:

- Auto-adjuster for lining wear

- Forcing rectifier (Fast response for crane hoists, etc.)

- Constant potential rectifiers (For crane bridges/trolleys)

- Terminal box rectifiers

TYPE “MBT” – 3 PH. AC AND DC

- Fast response – standard units < 2000 cycles per hour

- Spring applied, electrically released

- Continuously or Intermittent rated , Service < 40 Deg. C

- Class F insulation

- AC Supplies: 230-460-575/3Ph/50-60 Hz

- DC Supplies: 230V and 440V DC

Options:

- Auto-adjustor for lining wear

- External torque spring with calibrated indicator

- Externally adjustable, stepless time delays – both directions (set and release)

- Braketronic Controller

TYPE “MBM” – HYDRAULIC

- Hydraulically applied, spring release

- Pedal operation – One (1) or Two (2) Brakes

Options:

- Remote bleeding

Types “MBE” and “MST” – Electric – Hydraulic operated

Both types can be fitted with Pedal or Power assisted hydraulic over-ride to produce a dual-purpose brake. This hybrid brake is useful for EOT bridges, Gantry cranes and similar applications where dual control and/or emergency stopping and parking are required.

Mondel Industrial Shoe Brakes (200S)

Mondel Hi-Tork 200S range of industrial shoe brakes are suitable for a variety of industrial and mining applications which require reliable stopping and holding.

Mondel Hi-Tork 200S range of industrial shoe brakes are suitable for a variety of industrial and mining applications and environments including cranes, conveyors, moving bridges, fans, winches, turn-tables, overhead doors, lock gates, strip processing equipment, ship-loaders, ore bridges, deck machinery, machine tools and many other types of machinery which require reliable stopping and holding.

The 200S range is very flexible and consists of a basic movement which can be fitted with a variety of DC, AC, hydraulic, pneumatic and mechanical operators. The many optional features make the basic brakes suitable for a large number of different applications.

The main components of the movement are manufactured from cast steel, fabrications and close grained cast iron. The brake arms, shoes and several other components are standardized, jig drilled, and interchangeable between different brake types of the same diameter.

Specifications:

Type “MSA” – DC Magnet

- Spring applied, electrically released

- Magnet coils encapsulated in epoxy resin

- Class F insulation

- Shunt: 12V through 550V DC

- Series: 10A through 400A (40% – 10% FLC)

Options:

- Forcing rectifiers (Fast response for crane hoists, etc.)

- Constant potential rectifiers (For crane bridges, trolleys, etc.)

- Terminal box rectifiers

TYPE “MST” – 3 PH. AC AND DC

- Fast response – standard units 2000 cycles per hour

- Spring applied, electrically released

- Continuously rated or Intermittent, Service < 40 Deg. C

- Class F insulation

- AC Supplies: 230-460-575/3Ph/50-60 Hz

- DC Supplies: 230V and 440V DC

Options:

- External torque Spring with calibrated indicator

- Externally adjustable, stepless time delays-both directions (set and release)

TYPE “MSH” – HYDRAULIC

- Hydraulically applied by short stroke cylinder, spring release

- Pedal operation – One (1) or Two (2) Brakes

Options:

- Remote bleeding

Types “MSA” and “MST” – Electric-Hydraulic Operated

Both types can be fitted with assisted hydraulic over-ride to produce a dual-purpose brake. This hybrid brake is useful for EOT bridges, Gantry cranes and similar application where dual control and/or emergency stopping and parking are required.

Please contact Engineered Lifting for applications assistance with Mondel brake products.