When it comes to cable reels and cable reel application, you would be hard pressed to find a more dependable cable reel than a Gleason cable reel.

Engineered Lifting Systems has been designing applications around Gleason Reels for the last 10 years, and has had fantastic results. Gleason Reels can be designed to meet the most demanding applications. We have used them in Steel Mills, Paper Plants, Automation, and Magnet service.

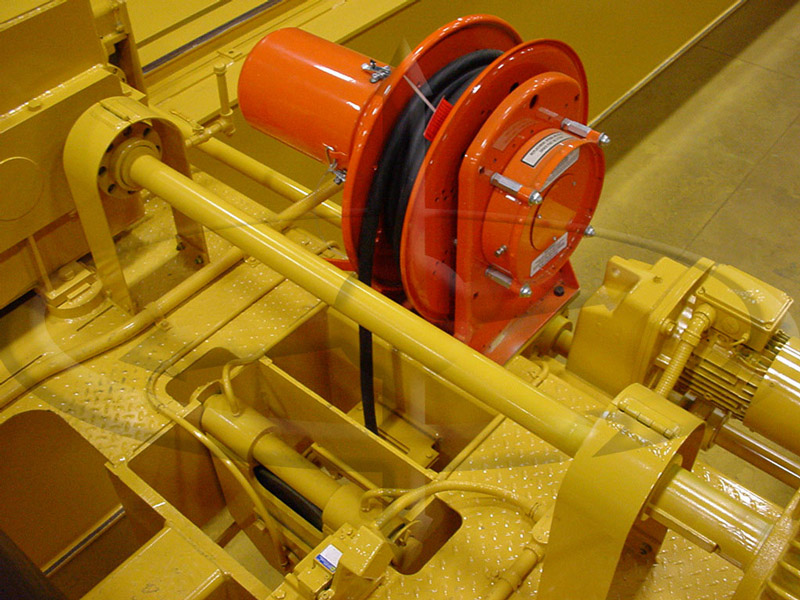

Here is a Gleason MMD28 mill duty cable reel just prior to start-up, on a Class F magnet service crane.

At face value, the application of an electric reel looks pretty straight forward. However the details of the use and service with the correct reel and cable selected will get you the best results. Engineered Lifting Systems has application engineers ready to help you.

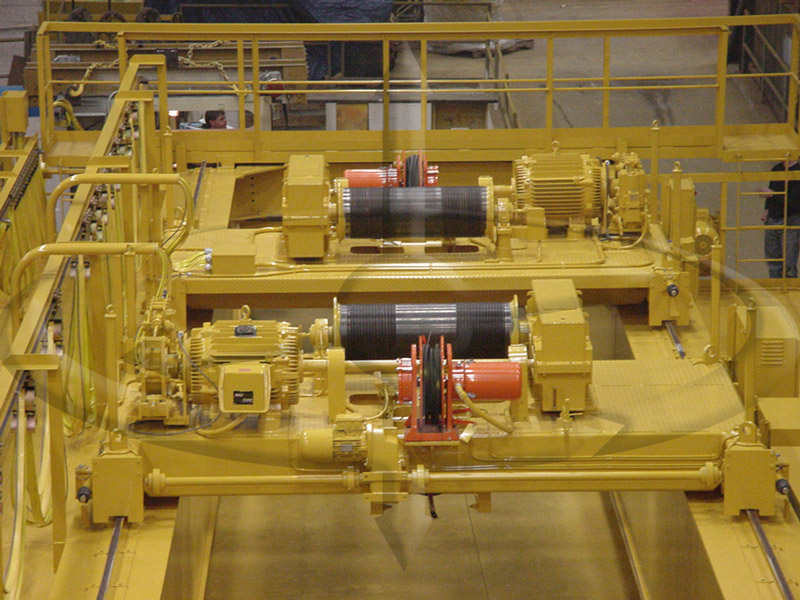

These two Gleason SHO reels were photographed just before we installed them. They were part of a comprehensive modernization on an automated magnet stacker crane. (NOTE: Magnetek DMC magnet controllers were used.)

These reels feature a Monospiral wrap spool. The Monospiral wrap is recommended where equipment is running automatically or semi-automatically and where there are no operators near the equipment. This method requires more space for the spool given an equal amount of travel/storage space than a conventional reel spool, but the cable will wrap and unwrap consistently.

In a “lift” application, Gleason Reels can be used to power bottom block rotation, below the hook grabs, and coil lifters. The below pictures show Gleason reels applied to Class E trolleys. (Special thanks to Superior Crane Corp for use of the pictures!)

If you have an application for a cable reel, or just questions on the best way to bring electric or air power to your equipment, please call Engineered Lifting Systems at 866-756-1200 today or contact us online.