U-S Safety Trolley Four-Bar Electrification …

U-S Safety Trolley Four-Bar Electrification use with Gorbel Workstation Systems

There are customers that have specific application conditions that limit the use of a conventional festoon installation for Workstation systems, so a rigid bar system is used. Some of these issues can be:

- End approach

- Multiple cranes or trolleys

- Low headroom clearances

- Aesthetics (overall system appearance)

One of the bar systems that has been used for Workstation systems is the U-S Safety Trolley Four-Bar electrification bar. We have one customer who has purchased a considerable amount of this specific brand and style of electrification for dozens of Workstation systems, and has had problems with shocking the operators at the load chain and hook.

Engineered Lifting Systems was brought in to diagnose the problem with shocking after several “events” of shocking on different systems took place.

It’s important to note that the need for a solid ground at the pendant and hoist control is important, as the wheels on all Gorbel Workstation systems are made from a non-conductive polymer material.

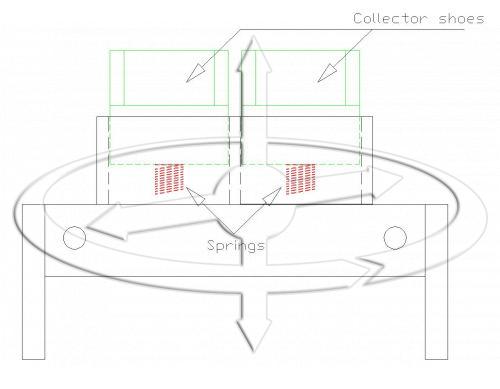

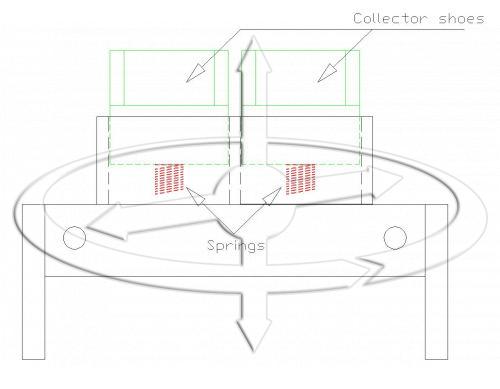

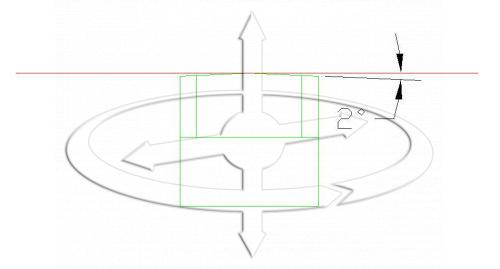

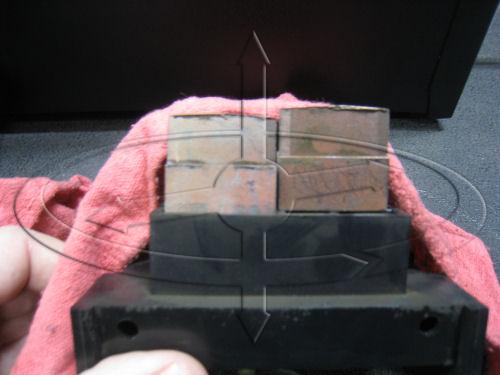

After testing several systems and Four-Bar collectors we found that the design of the collector may lead to the shoe wearing poorly. Please see the below illustrations:

The above is an illustration of the collector assembly.

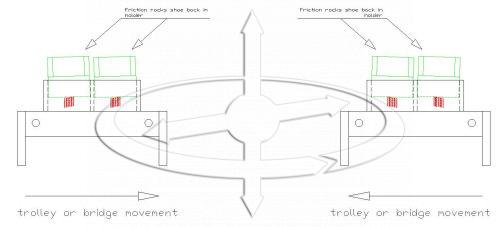

The above illustration and video shows what happens as the collector slides up and down the bar system, pushing the shoe at an angle. Click here to open the video in a new browser window.

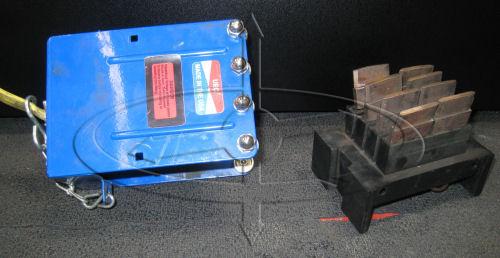

The above illustration and picture show the measure 2 degree slope on both the front

and back of the shoe, leaving a point or crown in the middle of each shoe.

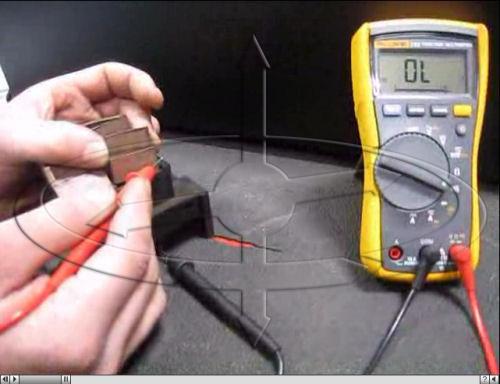

The above video was pretty typical for the collectors we reviewed, along with the crowning in the middle.

Click here to open the video in a new browser window.

The problem is really compounded when we found that when the bridge or trolley motion comes to rest that specific shoe in the collector assembly actually would balance on the crown or point of the shoe on the conductor bar. When considering the limited contact area, and the amount of resistance in the shoe, it was easy to see how 110 volts from the control circuit was getting to the load chain and hook on a simple contactor control. A hoist with a variable frequency drive has a negative side that goes to ground, and without a proper ground it would also be able to hit the operator.

We felt there was another more troubling issue that could happen. In the event that the motor shorted and one leg were to go to ground, that would place 277 volts at ground and potential for serious injury could occur.

At this time, Engineered Lifting Systems suggests using the standard flat wire electrification on any Workstation cranes or jibs if at all possible. The festoon system offers the best protection from loss of a ground, and provides the least amount of friction for the operation of the Gorbel system.

Eric “The Crane Doctor”

866-756-1200

ebrown@engineeredlifting.com

Recent news posts

Gravity Latch with Rotation Lock

Magnetek Series 3 Drives Using “Motor 2” Option

Magnetek Brake Circuit Fusing

Crane Cab Replacement Improves Function