Engineered Lifting Systems was recently contacted to provide our gravity latches on several cranes at an automotive stamping plant.The existing hooks were in great shape, but came from a time when hooks were not provided with safety latches. Not only interested in complying with current OSHA standards, the end user’s safety manager wanted a way for the operators to keep their fingers and thumbs out of the hook throat when loading and unloading the hook bail with heavy oblong rings.These cranes were 40-ton capacity with 40-ton main, and 10-ton auxiliary hoists. As a part of the operation, they regularly lifted 100% capacity dies and components associated with stamping plant operations.

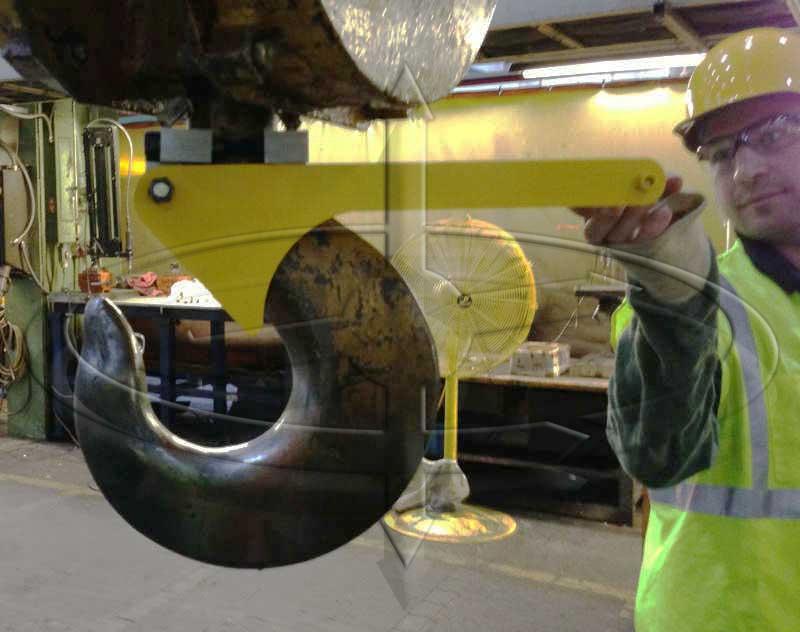

Engineered Lifting Systems was there to help the plant maintenance personnel install the new latches, as well as testing them out.

10-ton Auxiliary Hoist

Click on images for a larger view.

Before.

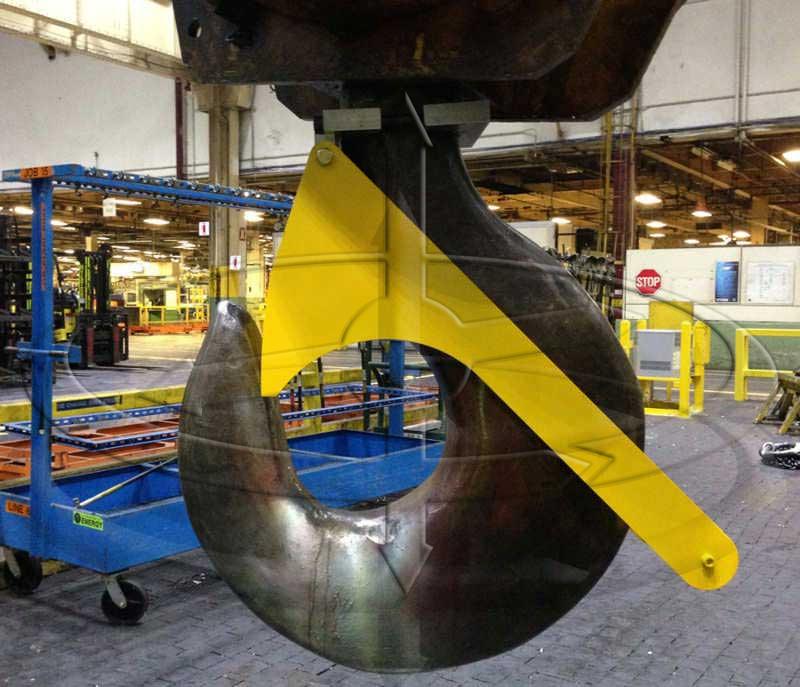

40-ton Main Hoist.

Prior to the installation of the gravity safety latch.

After the gravity safety latch installation.

After months of use, the latches are providing great service and added safety. You can see from the picture that the operator’s hand is well behind the latch throat opening. In addition, these latches can be pinned open and closed.Using these latches saved the plant thousands in replacement hooks, and they have a better, stronger and safer latch.

If you need help with a safety latch, or any crane application, please contact Eric Brown (the Crane Doctor) via phone at 800-756-1200, email at ebrown@engineeredlifting.com or complete our quick form!

Recent news posts

Gravity Latch with Rotation Lock

Magnetek Series 3 Drives Using “Motor 2” Option

Magnetek Brake Circuit Fusing

Crane Cab Replacement Improves Function