Custom Crane Installation – Gorbel Cr …

Custom Crane Installation – Gorbel Cranes Are Fast!

Recently, Engineered Lifting Systems was contracted to design, provide and install a Gorbel Workstation Crane System. The basis for the system was to furnish a 2,000# capacity runway for two 1,000# Gorbel ergonomic bridge cranes. We took several pictures along the way to help show how the installation progressed.

With a survey at the time of order entry, we determined the exact dimensions of the building to make sure the Gorbel system was ordered to fit into the building and provide the hook travel requirements.

This installation was made easier with an open room at the time of installation.

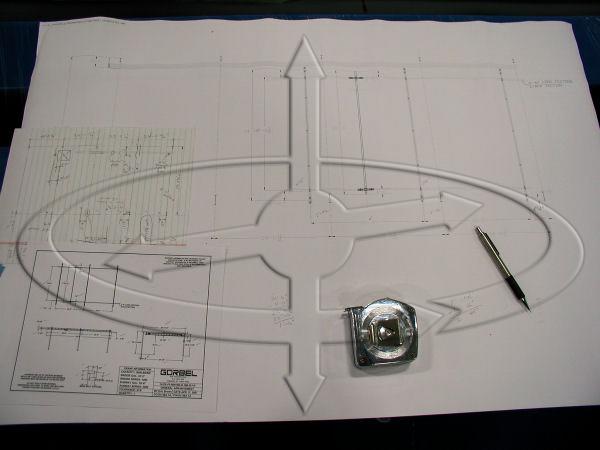

The Gorbel system is laid out and ready for installation.

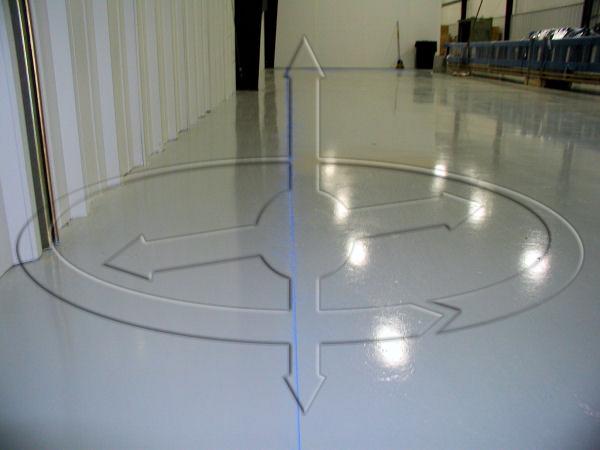

Before erecting the columns, we needed to lay out where the columns were going to be placed.

Every system starts with a good construction line.

After making sure that the column grid was laid out precisely, and the centers of the columns were marked, it was time to start putting up the columns.

Once a column was up, it was time to drill holes into the floor to use for the anchor bolts.

After anchoring each of the six columns, they were brought into plumb. The metal shipping straps that were used to hold the columns together for shipment are very handy shim material.

Once all six columns are up and plumb, it is time to place the headers.

Here is a picture of Dane Vance in the action bolting up the first header.

After installing each of the headers, it was time to put up the runway. And roll on the crane. The finished project up and ready for customer use!

Remember, although Gorbel offers standard crane systems, Engineered Lifting Systems can supply a custom design to allow column placement and hook travel to match YOUR needs.

Contact Engineered Lifting today to discuss your application! We handle the complete Gorbel crane product line including bridge cranes, monorail systems, jib cranes, articulating jib cranes and more.

Recent news posts

Gravity Latch with Rotation Lock

Magnetek Series 3 Drives Using “Motor 2” Option

Magnetek Brake Circuit Fusing

Crane Cab Replacement Improves Function