30-Ton Overhead Crane Gets New Girder Conne …

30-Ton Overhead Crane Gets New Girder Connections

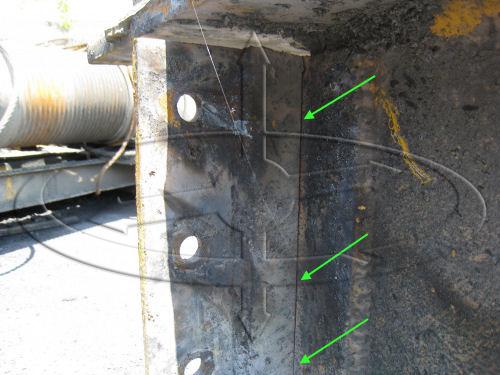

During a recent service inspection, Engineered Lifting System’s service technicians discovered substantial cracks in the girder connections on a double girder top running 30-ton. All four girder connections were cracked or broken from years of service, as well as resulting cracks in the girders.

Due to the nature of this crane’s use in the customer’s facility, it was critical to have the crane repaired quickly, and correctly. Often one or two small cracks in connections, girders, or even endtrucks can be performed with the crane on the runway. However this crane required an extensive repair, and had to be removed from the runway.

That’s a big crack!

All four girder connections looked at least this bad.

Teaming up once again with Superior Crane in Milwaukee Wisconsin, we developed a solution to remove the crane from service, ship the crane to Superior, replace the girder connections and re-span the crane on an emergency basis. This was completed in 4-weeks!

While the crane was on the ground, critical repairs and preventative maintenance was completed on the trolley and hoists, including rebuilding all of the brakes, replacing seals, oil, brake wheels, worn couplings, main hoist input shaft, equalizer sheaves and shafts, and installing new load cables.

New girder connections with new lateral plate.

Another connection replaced.

Annual crane and hoist inspection is not only a mandatory OSHA requirement but also an important factor for the safety of your workers and the reliability and productivity of your work processes.

The girder connection repairs/replacements together with the repairs on the trolley and hoists placed this crane back into VERY active service.

If you have a crane that need structural repairs, don’t worry. Call Engineered Lifting Systems and let us handle your problems!

Or, contact Your Crane Doctor…..Engineered Lifting

Recent news posts

Gravity Latch with Rotation Lock

Magnetek Series 3 Drives Using “Motor 2” Option

Magnetek Brake Circuit Fusing

Crane Cab Replacement Improves Function