For years, AC crane users have enjoyed the benefits of Magnetek variable frequency crane controls, giving them low operating costs and lowering mechanical costs due to high starting and stop forces on the crane. Traditional AC contactor based controls just do not provide the features and trouble shooting characteristics of a Magnetek VFD drive.

But what about you DC guys? Saddled with old magnetics, series or shunt DC motors operating at rpms that impede or prevent conversion to AC squirrel cage motors, with arcing contact tips, high inrush, gearboxes sized for the motors making your life a nightmare? Not anymore….

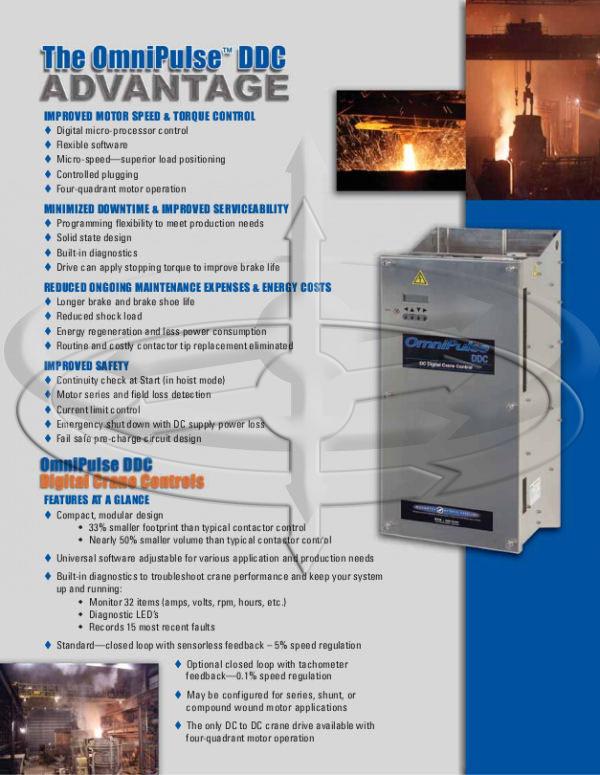

Introducing Magnetek OmniPulse DDC digital DC crane drives! The same quality, operational ease, and rugged design that goes into every P3, G+, VG+ drive now goes into the OmniPulse DC drive. Got shunt motors? Got Series motors? No problem! These drives provide instant performance and reliability into your DC overhead crane that old static or magnetic controls cannot touch. These drives cut maintenance expenses and energy costs on the electric side, but imagine how reduced your mechanical repairs and maintenance will be with programmed acceleration and deceleration rates that the operator cannot defeat!

Engineered Lifting Systems recently installed another OmniPulse drive, replacing an old 4 speed DC magnetic system. Many times, and as was the case in this modernization, we are able to use the old DC enclosure and simply replace the old back plate with controls with the new pre-wired Magnetek sub-panel. Our Service Manager and Head Field Engineer, Dane Vance, said “The installation went without a hitch, and the drive was as easy to program as any Magnetek product, with fantastic control of the crane”.

Before.

After.

The first thing you notice is the limited amount of wiring within the controls. But also notice that for DC the interconnection to the existing panel wires is limited, making this type of conversion fast and simple. Please see the brochure for more information, or just contact Eric Brown at Engineered Lifting Systems.

Note: No resistors, brakes or motors were harmed during the performance of this installation; in fact they were left as existing except without an enclosure. The installation was monitored by the NAPCEC (the National Association for the Prevention of Cruelty to Electrical Components) and exceeded their highest expectations – just like OmniPulse.

Download our Benefits of Upgrading Existing Cranes white paper in PDF and learn more about Magnetek’s complete range of systems for improving the performance and reliability of your cranes.

Recent news posts

Gravity Latch with Rotation Lock

Magnetek Series 3 Drives Using “Motor 2” Option

Magnetek Brake Circuit Fusing

Crane Cab Replacement Improves Function