Weidmuller Authorized Distributor

A Weidmuller Authorized Distributor supports industrial control systems where reliability, serviceability, and predictable behavior shape long-term decisions. At Engineered Lifting Systems, our role is to make sure Weidmuller components support real workflows without disruption—inside control panels that run production every day.

We work with Weidmuller relays, power supplies, terminal blocks, and related hardware where they actually live: inside control cabinets supporting cranes, heavy equipment, and other industrial systems. If you need help with part selection, replacement, or troubleshooting based on how your equipment really operates, call 866-756-1200 or contact us online to talk with our Weidmuller Authorized Distributors.

Learn More About

- What Weidmuller components do inside industrial control panels

- Industries and applications that rely on Weidmuller control hardware

- Common control-related issues tied to power, wiring, and component selection

- How ELS works with Weidmuller equipment in real control panels

- Where Weidmuller relays fit into lifting and material handling systems

- Why terminal blocks and panel wiring matter for long-term serviceability

- The role of power supplies, protection, and monitoring in stable controls

- Answers to common Weidmuller selection and support questions

- Why working with an authorized Weidmuller distributor matters

- How to talk with ELS Weidmuller distributors in St. Louis

Weidmuller Components in Industrial Control Systems

Weidmuller supplies the core electrical building blocks used inside industrial control panels—relays, terminal blocks, power supplies, and supporting hardware that manage how power and signals move through equipment.

As a Weidmuller authorized distributor, Engineered Lifting Systems works with these components where they actually live: inside control cabinets supporting cranes, material handling equipment, and other industrial systems. That work spans part selection, replacement, troubleshooting, and panel-level upgrades as systems evolve.

Industries That Rely on Weidmuller Control Components

Weidmuller components show up in industries where control systems need to stay predictable under real operating conditions—not just at startup, but after years of changes, expansions, and maintenance cycles. In these environments, working with a Weidmuller authorized distributor helps keep power delivery, wiring structure, and panel hardware aligned with how equipment actually operates. Clean layouts and serviceable panels directly affect uptime, safety, and troubleshooting accuracy.

- Overhead lifting and material handling: Cranes, hoists, and automated handling systems where control reliability directly affects load movement and safety.

- Manufacturing and fabrication: Facilities running multi-shift equipment where panel stability and long-term serviceability matter more than quick fixes.

- Distribution and logistics: Conveyor-driven systems that depend on consistent control behavior to maintain throughput and avoid cascading stoppages.

- Process and batch operations: Systems where signal integrity, power stability, and accurate panel documentation matter as equipment evolves.

- OEMs and system integrators: Teams building or updating panels that need standardized components which remain manageable well beyond commissioning.

If any of these environments sound familiar, contact our team to work with a Weidmuller authorized distributor focused on components that match how your equipment actually runs—not just how it was originally drawn.

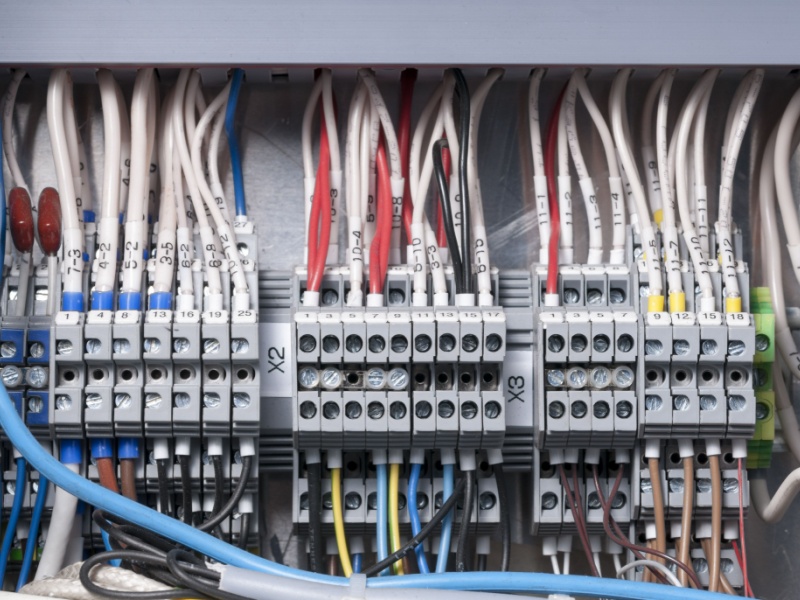

![[city], [state], Weidmuller Distributors - Authorized Weidmuler Parts Dealers in St. Louis, MO](https://www.engineeredlifting.com/wp-content/uploads/Weidmuller-authorized-distributors-parts-dealers.jpg)

Common Control-Related Issues in Overhead Lifting Equipment

When equipment starts acting strange, it rarely shows up as a clean, obvious failure. What people notice first are patterns—controls dropping out, devices not lasting as long as expected, or machines behaving differently under the same operating conditions.

In many cases, those symptoms trace back to how power and signals are being handled inside the control panel. Common issues include:

- Power and control hardware stretched beyond the panel’s original design

- Components wearing out faster than expected once loads and duty change

- Intermittent issues tied to electrical noise (EMI) or grounding inconsistencies

- Connections or wiring damaged during maintenance or retrofits

- Control panels that no longer reflect your current control system layout

- Replacement parts that fit on paper but behave differently in the field

Independently, these issues can feel minor. Over time, they tend to stack—turning small inconsistencies into nuisance faults, unpredictable behavior, or systems that no longer respond the way anyone expects.

What We Do With Weidmuller Equipment

Being an authorized Weidmuller distributor gives our team access to parts—but more importantly, it gives us a working understanding of how those components behave, how they’re installed, what powers them, and what keeps them running.

At the component level, we support Weidmuller part selection, replacement, troubleshooting, and repair inside real industrial panels that support and control heavy lifting operations.

Weidmuller Relays

Relays play a quiet but critical role in heavy lifting and material handling systems. They don’t physically move loads or generate torque, but they do control when power is allowed to reach the components that need it. This places relays directly between control logic and physical motion—especially in crane and lifting applications where timing, sequencing, and predictability matter. For teams working with a Weidmuller authorized distributor, relay selection often becomes one of the first places control behavior either stabilizes or starts to drift.

- Protection between control and power: Relays sit between PLC outputs and field devices, keeping control electronics from carrying current, noise, or voltage they were never designed to handle.

- On/off timing control: Relays determine when motors, brakes, valves, and other devices energize or drop out, directly affecting how equipment starts, stops, and responds.

- First point of wear: Frequent switching, inrush/startup current, vibration, heat, and imperfect power conditions tend to show up at the relay before they show up anywhere else.

- Early warning inside the panel: Relay chatter, delayed response, excess heat, or inconsistent operation often surface at the relay when something in the panel isn’t quite right.

- Consistency in lifting behavior: Stable relay operation helps keep lifting and handling equipment behaving the same way from cycle to cycle and shift to shift.

Relays sit at the intersection of control and power. Small differences in selecting the wrong Weidmuller (or other) relay component in stressful operating conditions can have serious effects in heavy lifting applications. Factors like contact ratings, coil voltage quality, switching frequency, suppression, ambient heat, and load behavior at startup all influence how a relay behaves once installed.

Matching Weidmuller relays to how a panel actually operates—something we see firsthand in overhead crane and lifting systems—is a core reason teams work with a Weidmuller authorized distributor instead of treating relays as interchangeable line items.

Weidmuller Terminal Blocks & Panel Wiring

We work with Weidmuller terminal blocks in control panels where long-term clarity, vibration resistance, and service access matter. As a Weidmuller authorized distributor, that work starts with understanding how panels are actually wired, serviced, and modified over time.

Terminal blocks are the backbone of a clean, understandable control panel. They don’t switch loads or execute logic, but they determine how control voltage, power, and signals are distributed, labeled, accessed, and serviced over the life of the equipment. In lifting and material handling systems, that quiet structure matters more than most people realize.

- Maintain order inside the panel: Terminal blocks create a consistent, organized way to land control wiring, power distribution, grounding, and I/O signals so circuits stay readable long after installation.

- Stable electrical connections: Properly matched terminal blocks maintain consistent contact pressure over time, helping signals and control voltage behave the same way day after day.

- Support for service and changes: Well-laid-out terminals make it easier to trace circuits, isolate issues, and make updates without disturbing adjacent wiring or adjacent components.

- Tolerance for real-world conditions: In cranes and lifting equipment, vibration, movement, and heat are unavoidable. Terminal blocks are designed to hold connections steady even when the surrounding environment isn’t.

- Foundation for predictable behavior: Clean terminations reduce electrical noise, resistance, and signal variability that can quietly affect how relays, drives, and controls behave.

When panels are easy to understand and wiring behaves consistently, troubleshooting stays straightforward and small changes stay small. For teams working with a Weidmuller authorized distributor, terminal blocks often determine whether a panel remains serviceable—or slowly becomes a liability—as equipment ages, loads change, and modifications are made.

Weidmuller Power Supplies, Protection, and Monitoring

Control systems only behave as well as the power feeding them. In lifting and material handling equipment, stable DC power keeps logic, relays, and control circuits doing the same thing every time a command is issued.

Power supplies

Weidmuller power supplies provide the control voltage that feeds PLCs, relays, sensors, and I/O inside the panel. Their job isn’t just conversion—it’s staying stable while motors start, crane brakes engage, and loads change.

Power supplies are critical if you want to:

- Maintain consistent control voltage during load transitions

- Support mixed control loads without nuisance power drops or resets

- Ride through voltage sags, transients, and uneven incoming power without destabilizing the panel

Protection and monitoring

Protection and monitoring components keep small electrical problems from turning into system-wide issues—and make it obvious when control power isn’t behaving the way it should.

- Isolate faults, overloads, and transient events before they spread

- Provide clear indication when control power drifts or drops

- Help maintenance teams identify electrical issues without guesswork

Our authorized Weidmuller parts dealers use these components to create stable electrical baselines. When control power stays clean and visible, relays switch cleanly, logic stays predictable, and troubleshooting stays focused instead of reactive.

Frequently Asked Questions

Practical questions we hear when teams are working with Weidmuller components inside active control panels.

Do I need a Weidmuller authorized distributor to buy parts?

What information helps when sourcing or replacing a Weidmuller component?

How does a Weidmuller authorized distributor help with older or modified panels?

Can Weidmuller components be mixed with other brands in the same control panel?

When should components be reviewed during a panel upgrade or expansion?

Can a Weidmuller authorized distributor prevent behavior changes after part replacement?

Can a Weidmuller authorized distributor help with discontinued or hard-to-source parts?

Why Work With an Authorized Weidmuller Distributor?

Being a Weidmuller authorized distributor matters when components need to behave predictably inside real control panels—not just match a part number. At Engineered Lifting Systems, our work with Weidmuller equipment is grounded in how relays, power supplies, and panel hardware interact under load, over time, and through system changes.

As authorized Weidmuller distributors, we support:

- Weidmuller component selection that aligns with how panels actually operate

- Troubleshooting and replacement when control behavior starts to drift

- Panel rebuilds, upgrades, and standardization projects

- Long-term serviceability as systems expand or evolve

That support often overlaps with broader electrical, mechanical, and modernization work across lifting and material handling systems.

Talk to Our Authorized Weidmuller Distributors in St. Louis

Engineered Lifting Systems also supports related services and systems where Weidmuller components are commonly applied:

- Crane Modernization

- Overhead Crane Automation

- Crane Repair

- Process Cranes

- Crane Inspection

- NORD Gearbox Parts

If you’re dealing with unstable controls, aging panels, or upcoming upgrades—or want to avoid those problems altogether—contact our team or call 866-756-1200 to talk through your Weidmuller requirements. We’ll help you choose components that behave the way your equipment needs them to, not just the way the drawing says they should. Work with a Weidmuller Authorized Distributor now that understands real-world operations and these specific components’ functions.