Crane Parts St. Louis, MO

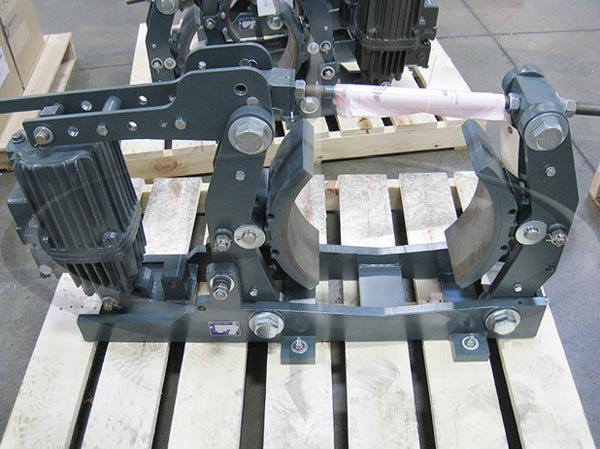

Crane Parts St. Louis, MO. Engineered Lifting Systems provides crane parts and accessories to St. Louis, MO industries and businesses, as well as throughout the Midwest, that need reliable and effective parts for their cranes. Your processes and systems demand high-quality parts, and we only provide parts that are proven to deliver at every level of shipping and manufacturing.

Established in 2004 in St. Louis, MO, Engineered Lifting Systems is St. Louis, MO’s solution for the parts and accessories that you demand for your crane. We always look to consult with St. Louis, MO customers first to achieve the best results possible. But, we understand, sometimes that’s not feasible. You needed that part in St. Louis, MO yesterday. Not a problem, we are on it. To get a quote for a part or to speak with our team immediately, give us a call at 866-756-1200 or 866-756-1202 or contact us online.

In addition to being the go-to crane parts company in and around St. Louis, MO and throughout the Midwest, Engineered Lifting Systems also provides the following for our St. Louis, MO customers:

- Weidmuller Distributor

- NORD Drivesystems Distributor

- NORD Gearbox Repair

- NORD Distributor

- Process Cranes

- Weidmuller Parts and Repair

- NORD Flexbloc Parts

- NORD Flexbloc

- Overhead Crane Inspection

- Overhead Crane Repair

Providing an Unparalleled Supply of St. Louis, MO Crane Parts

We keep an extensive stock of crane parts and accessories in supply to guarantee that St. Louis, MO businesses can remain functional at any hour. If your crane breaks down in the St. Louis, MO area, and you aren’t certain which part you need, our specialists can help. We also offer crane inspection services to certify what parts your crane may need, as well as crane modernization services if your piece of equipment is too dated for your current needs in St. Louis, MO. Our unrivaled inventory of crane parts near St. Louis, MO includes:

Crane Parts For Every St. Louis, MO Business, Near and Far

Safety and top customer service are our main priorities at Engineered Lifting Systems. We have an elaborate history of providing exceptional crane services in the St. Louis, MO area, and we are proud to be able to share our experiences with our St. Louis, MO clients. Call us today at 866-756-1200 or 866-756-1202 or contact us online. The following are several recent examples of the crane services we provide St. Louis, MO businesses and operators:

- Crane Cab Replacement – Engineered Lifting Systems was asked to evaluate an existing application of a predominantly cab operated shipping crane. The review covered crane reliability, control method, and cab operator ergonomics. The cab, as provided by the original crane manufacturer, was smaller, had some specific line of sight issues, and was not designed with the thought of an operator working in the cab for 10-12 hours per day. Collaborating with the plant operators and maintenance, we built a list of items that would make the use of the cab more productive, including: adjustable crane cab chair locations and elevations, increase – or provide in some cases – line of sight to particular daily repeated production operations, and decrease operator fatigue.

- Class F Control House and Crane Modernization – This particular crane service summarizes the upgrade of an existing 55-ton capacity Class F magnet service overhead crane. There was a bevy of issues on the trolley and, with limited time during shutdowns, we believed that completely replacing the hoist and trolley was more time- and cost-effective.

- Magnetek Series 3 Drives Utilizing “Motor 2” Option – Engineered Lifting Systems was contracted to travel to a fairly remote location in Panama to help a Magnetek user with a hydroelectric overhead crane. Panama has many hydroelectric plants scattered across the country. These plants provide the majority of the electricity for the country. The plants are generally smaller than what we think of here in the United States (the Hoover Dam), but are an important part of the Panamanian power grid.

Reach Out to Us Today For the Best in St. Louis, MO Crane Parts | Engineered Lifting Systems

Engineered Lifting Systems has made its name by providing quality parts and services right when St. Louis, MO businesses need them. Heavy duty cranes keep your St. Louis, MO operation running and when they sputter, so too does your productivity. When a crisis like this occurs near St. Louis, MO, you need ELS crane engineers to fix the issue as quickly as possible.

When your crane operation is at a standstill anywhere in the St. Louis, MO or throughout the Midwest, Engineered Lifting Systems is the team to call. Our parts and services keep companies running and operating on point, and we’re pleased to be the crane parts and repair company of choice for St. Louis, MO and Midwest industries. Give us a call today at 866-756-1200 or 866-756-1202 or contact us online.